publicaciones

revisa aquí mis diferentes artículos en revistas científicas!

2023

-

Sustainability of cellulose micro-/nanofibers: A comparative life cycle assessment of pathway technologiesSergi Arfelis, Roberto J. Aguado, Didem Civancik, and 4 more authorsScience of The Total Environment, 2023

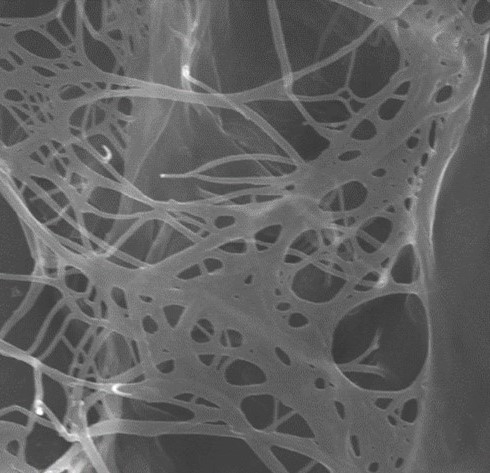

Sustainability of cellulose micro-/nanofibers: A comparative life cycle assessment of pathway technologiesSergi Arfelis, Roberto J. Aguado, Didem Civancik, and 4 more authorsScience of The Total Environment, 2023Cellulose micro- and nanofibers (CNFs) are commonly regarded as “greener” than petro-based materials. The high energy input that their production still demands, along with the use of chemicals or heat in some pretreatments, asks for a critical view. This paper attempts a life cycle assessment of CNFs produced from bleached hardwood kraft pulp via three different pre-treatments before mechanical homogenization. First, a fully mechanical route, based on a Valley beating pre-treatment. Second, an enzymatic route, based on endoglucanases and requiring certain temperature ( 50 °C). Third, a TEMPO-mediated oxidation route, considering not only the impact of the chemical treatment itself but also the production of TEMPO from ammonia and acetone. The main output of the study is that both, mechanical and TEMPO-mediated oxidation routes, present lower impacts than the enzymatic pre-treatment. Although the mechanical route presents slightly milder contributions to climate change, acidification, eutrophication, and other indicators, saying that TEMPO-mediated oxidation is environmentally unfeasible should be put under question. After all, and despite being disregarded in most assessment publications up to date, it is the only well-known way to selectively oxidize primary hydroxyl groups and thus producing kinds of CNFs that are unthinkable by other ways.

@article{ARFELIS2023162482, title = {Sustainability of cellulose micro-/nanofibers: A comparative life cycle assessment of pathway technologies}, journal = {Science of The Total Environment}, volume = {874}, pages = {162482}, year = {2023}, issn = {0048-9697}, doi = {https://doi.org/10.1016/j.scitotenv.2023.162482}, url = {https://www.sciencedirect.com/science/article/pii/S0048969723010987}, author = {Arfelis, Sergi and Aguado, Roberto J. and Civancik, Didem and Fullana-i-Palmer, Pere and Pèlach, M. Àngels and Tarrés, Quim and Delgado-Aguilar, Marc}, keywords = {Enzymatic hydrolysis, Life cycle assessment, Mechanical treatment, Nanocellulose, Pulp and paper, TEMPO-oxidized cellulose nanofibrils}, } -

Life cycle assessment on calcium zincate production methods for rechargeable batteriesSergi Arfelis, Irene Malpartida, Valentin Lair, and 4 more authorsScience of The Total Environment, 2023

Life cycle assessment on calcium zincate production methods for rechargeable batteriesSergi Arfelis, Irene Malpartida, Valentin Lair, and 4 more authorsScience of The Total Environment, 2023The world’s energy transition from fossil to renewable energy is unthinkable without further research in energy storage. Decreasing the environmental impacts from the production of energy storage technologies is essential for achieving a green energy transition. Calcium Zincate (CAZN) is used as active material in rechargeable zinc-based batteries (and other products, such as heterogeneous catalysts for biodiesel or antifungal products). They present a low-cost, safer, alternative to Lithium based batteries and are targeted as replacement solutions for lead-acid batteries. We propose a novelty in the synthesis of CAZN, the hydro-micro-mechanical process (HMMS). The residence time of this new route is about 20 times lower than the traditional processes, so its production needs less infrastructure and can deliver quicker at an industrial scale. In addition, laboratory tests indicate that HMMS CAZN has more reaction surface area and the activation of the battery is 1.77 times faster. Using the life cycle assessment (LCA) method, we compare this new process with the current best option, hydro-thermal synthesis (HTS). The cradle-to-gate results per kg of CAZN already indicates that HMMS is an environmentally better alternative for all indicators; especially when considering the normalization of the results with the residence time and the surface area, HMMS delivers better results, with improvements of 97 % in global warming, for instance. With this, we demonstrate that, outside of the cradle-to-gate, variables that make the final products better service units or give more function should be considered as valuable additional information when deciding among alternatives. This also highlights the importance of life cycle thinking when working with chemical processes and substances. In the sensitivity analysis, we developed 7 scenarios related to the energy demand of the processes, and we incorporated the projection in the European electricity mix for 2030 and 2050.

@article{ARFELIS2023161094, title = {Life cycle assessment on calcium zincate production methods for rechargeable batteries}, journal = {Science of The Total Environment}, volume = {866}, pages = {161094}, year = {2023}, issn = {0048-9697}, doi = {https://doi.org/10.1016/j.scitotenv.2022.161094}, url = {https://www.sciencedirect.com/science/article/pii/S0048969722081979}, author = {Arfelis, Sergi and Malpartida, Irene and Lair, Valentin and Caldeira, Vincent and Sazdovski, Ilija and Bala, Alba and Fullana-i-Palmer, Pere}, keywords = {Life cycle assessment, Calcium zincate, Mechanochemistry, Zinc-batteries, Ball-milling}, }

2022

-

Life cycle assessment of PE and PP multi film compared with PLA and PLA reinforced with nanoclays filmAlba Bala, Sergi Arfelis, Helena Oliver-Ortega, and 1 more authorJournal of Cleaner Production, 2022

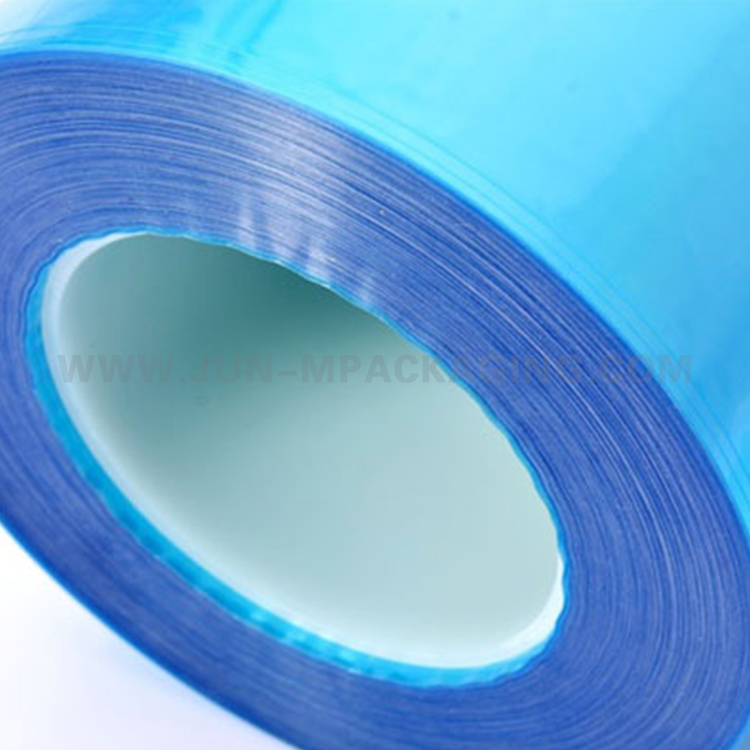

Life cycle assessment of PE and PP multi film compared with PLA and PLA reinforced with nanoclays filmAlba Bala, Sergi Arfelis, Helena Oliver-Ortega, and 1 more authorJournal of Cleaner Production, 2022Plastic has become essential for our economy and the packaging industry. However, plastic use is linked to environmental problems such as waste generation and loss of resources, since only 42% of the plastic used for packaging purposes is recycled. Another problem associated with the use of plastic materials is caused by their abandonment in the environment since they are non-degradable polymers. This paper analyses the environmental performance of using biodegradable poly-lactic acid bags, pure (PLA) and reinforced with nanoclays (PLA + NC), in comparison to conventional alternatives made of polyethylene (PE) and polypropylene (PP) for being used to pack fresh bakery products. The results reveal that for Climate Change and Fossil Resources use, PLA + NC performs better than the alternatives. In the case of Climate Change, it has 45% less impact than low density polyethylene (LDPE), 39% less than PP, and 2% less than PLA. However, the use of PLA + NC, results in higher impacts on Land Use and Water Use, because this is produced from crops. Compared with PLA, PLA + NC has 5% less impact on these impact categories, but between 99 and 100% more impact on Land Use and between 79 and 81% more impact on Water use than PP and LDPE. Thus, poly-lactic acid bags reinforced with nanoclays are shown as an alternative for fossil-based polymers (PE and PP) for certainty type of applications when we focus on Climate Change and Fossil resources use reduction. In this sense, the results also reveal that the most environmentally friendly end-of-life for PLA and PLA + NC is incineration instead of composting.

@article{BALA2022134891, title = {Life cycle assessment of PE and PP multi film compared with PLA and PLA reinforced with nanoclays film}, author = {Bala, Alba and Arfelis, Sergi and Oliver-Ortega, Helena and Méndez, José Alberto}, journal = {Journal of Cleaner Production}, volume = {380}, pages = {134891}, year = {2022}, issn = {0959-6526}, doi = {https://doi.org/10.1016/j.jclepro.2022.134891}, url = {https://www.sciencedirect.com/science/article/pii/S095965262204464X}, keywords = {Bioplastic, Circular economy, Sustainable waste management, Poly-lactic acid, Composite materials} } -

Life cycle assessment as a tool for evaluating chemical processes at industrial scale: a reviewSergi Arfelis, Alba Bala, and Pere Fullana-i-PalmerGreen Chemistry, 2022

Life cycle assessment as a tool for evaluating chemical processes at industrial scale: a reviewSergi Arfelis, Alba Bala, and Pere Fullana-i-PalmerGreen Chemistry, 2022The present paper reviews 47 Life Cycle Assessments (LCA) applied to chemical reactions. The selection of the evaluated articles was conducted with a systematic literature review methodology. The review arises from the need to define the best methods for developing LCAs of chemical processes at industrial scale. The authors go through the stages defined in ISO 14040 and 14044, identifying both the gaps and the best techniques used in all the reviewed papers. The main difficulty observed when developing LCAs of chemical reactions is the lack of data due to confidentiality issues in chemical companies. In addition, this data is commonly only available at the laboratory scale. Laboratory data is sometimes directly upscaled without further consideration. Even though, simulation software, advanced calculations benchmarks, pinch analysis and retrosynthetic analysis are the best methods to estimate and scale up the mass and energy balances in the Life Cycle Inventory (LCI) stage. The article discusses these upscale procedures, makes a deep analysis of each single LCA stage, and assesses how chemical process information is managed, which is a novelty regarding previous reviews of chemical reaction LCA. From the Life Cycle Impact Assessment (LCIA) methodologies, they should be standardized to enable the comparability between LCAs of the same product. Both the European Commission and the Life Cycle Initiative are making progress in this regard. Eventually, the ReCiPe is the most used methodology among the reviewed papers. Finally, the article proposes different analyses to be performed in the interpretation phase: i.e., projecting the energy mix foreseen for the years 2030 and 2050 in energy-intensive processes or including other sustainability vectors (economic and social) in cross-cutting projects.

@article{D2GC02089K, author = {Arfelis, Sergi and Bala, Alba and Fullana-i-Palmer, Pere}, title = {Life cycle assessment as a tool for evaluating chemical processes at industrial scale: a review}, journal = {Green Chemistry}, year = {2022}, volume = {24}, issue = {20}, pages = {7751-7762}, publisher = {The Royal Society of Chemistry}, doi = {10.1039/D2GC02089K}, url = {http://dx.doi.org/10.1039/D2GC02089K}, } -

Techno-economic and environmental evaluation of a market pulp reinforced with micro-/nanofibers as a strengthening agent in packaging paperFerran Serra-Parareda, Roberto Aguado, Sergi Arfelis, and 3 more authorsJournal of Cleaner Production, 2022

Techno-economic and environmental evaluation of a market pulp reinforced with micro-/nanofibers as a strengthening agent in packaging paperFerran Serra-Parareda, Roberto Aguado, Sergi Arfelis, and 3 more authorsJournal of Cleaner Production, 2022Partly inspired by the concept of masterbatch in plastics manufacturing, we developed a strategy to improve the technical viability, the economic feasibility, and the environmental performance of lignocellulosic micro-/nanofibers. Instead of investing strenuous efforts in dewatering and/or drying nanocellulose suspensions to maximize their consistency without significantly hampering redispersion, which still stands as an unresolved challenge, we used them in high proportions (up to 50 wt%) to reinforce a high-yield pulp. The suspension can be dewatered-pressed (0.70–1.75 MPa) to obtain wet laps of never-dried reinforced pulps, or dried to consistencies over 90% to produce dry boards, but at the cost of lower strengthening capability. In any case, both wet and dry reinforced boards succeeded in enhancing the breaking length of a recycled pulp by up to 62% and 56%, respectively. In light of these results, we proposed a tentative upscaling and subsequent assessment of the process, evaluating different scenarios. From the technical point of view, reinforced pulp boards are much easier to handle and to deliver than dilute aqueous suspensions. In economic terms, savings in transportation costs are worth remarking. Last but not least, this strategy fulfills at least three goals associated with the concept of cleaner production: water recovery (internal recycling), lower CO2 emissions (especially if transportation takes place by road), and avoiding hazardous chemicals such as hypochlorite.

@article{SERRAPARAREDA2022131265, title = {Techno-economic and environmental evaluation of a market pulp reinforced with micro-/nanofibers as a strengthening agent in packaging paper}, journal = {Journal of Cleaner Production}, volume = {347}, pages = {131265}, year = {2022}, issn = {0959-6526}, doi = {https://doi.org/10.1016/j.jclepro.2022.131265}, url = {https://www.sciencedirect.com/science/article/pii/S0959652622008964}, author = {Serra-Parareda, Ferran and Aguado, Roberto and Arfelis, Sergi and Xifré, Ramon and Fullana-i-Palmer, Pere and Delgado-Aguilar, Marc}, keywords = {Chemical-free production, Lignocellulosic micro-/nanofibers, Masterbatch strategy, Nanocellulose, Transport emissions} } -

Architecture Development to Incorporate Industry 4.0 Solutions to Plastics Management: Circular EconomySergi Arfelis, Javier Rainer, and D. M. González-PérezIn Advances in Automation and Robotics Research, 2022

Architecture Development to Incorporate Industry 4.0 Solutions to Plastics Management: Circular EconomySergi Arfelis, Javier Rainer, and D. M. González-PérezIn Advances in Automation and Robotics Research, 2022The problems caused by plastic waste and the current situation of the sector make it necessary to rethink processes and business models to ensure the sustainability of the sector. The need to develop a circular economy in the plastics industry and the actions this entails have already been identified in the literature, together with analyses of how these needs might be met through the use of technologies and enablers of Industry 4.0. The objective of the research project reported here was the preliminary design of a plastic waste management network that integrates the technologies and concepts of Industry 4.0 and the principles of the circular economy. For this purpose, the Industrial Internet Reference Architecture (IIRA) methodology was used to cover all stages of the life cycle of plastic products. A model combining the use of Industrial Internet of Things (IIoT) and Artificial Intelligence (AI) technologies to optimize plastic waste management is presented here as a sustainable technological and economical alternative with the potential to improve environmental, social and corporate governance for greater sustainability of the plastics industry. The holistic methodology adopted enabled the development of a versatile, adaptable and scalable architecture that will be of interest to public and private actors in the plastics value chain.

@inproceedings{10.1007/978-3-030-90033-5_14, author = {Arfelis, Sergi and Rainer, Javier and Gonz{\'a}lez-P{\'e}rez, D. M.}, editor = {Moreno, H{\'e}ctor A. and Carrera, Isela G. and Ram{\'i}rez-Mendoza, Ricardo A. and Baca, Jos{\'e} and Banfield, Ilka A.}, title = {Architecture Development to Incorporate Industry 4.0 Solutions to Plastics Management: Circular Economy}, booktitle = {Advances in Automation and Robotics Research}, year = {2022}, publisher = {Springer International Publishing}, address = {Cham}, pages = {121--127}, isbn = {978-3-030-90033-5} }