biodiesel production

circular economy of biodiesel and valorisation of waste glycerol in solketal and CaDG

The EU is committed to achieving net-zero greenhouse gas emissions by 2050 through the European Green Deal and Paris Agreement. Transport, which currently relies heavily on fossil fuels, is a major contributor to global emissions and accounts for 25% of its global share. Road transport alone contributes 72% of overall transport emissions.

Biodiesel has the potential to reduce dependence on fossil fuels and associated greenhouse gas emissions, especially in heavy vehicles like ships. Biodiesel is expected to comprise 70% of transport fuel demand by 2040, with a projected shift in demand from 86.1 million to 110.6 million barrels per day by 2035.

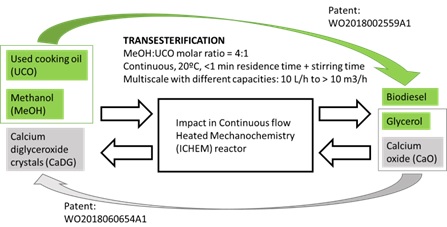

I’m working with Deasyl to convert used cooking oils into biodiesel, bridging the biofuels and waste management sectors (global UCO market is expected to reach €10.47 billion by 2028.). Glycerol, the by-product of the process, is used to produce solketal and CaDG, closing the biodiesel value chain. Solketal is used as an additive to improve fuel quality, while CaDG is the catalyst used by Deasyl in their process.

This innovative project has the potential to transform waste management and fuel production for a greener future.